Versatile Stainless Steel Fabrication for Multiple Industries

At Sumiparts SAS, we specialize in the design and fabrication of stainless steel products for a wide range of industries, delivering precision, durability, and superior quality in every project. Our stainless steel fabrication capabilities serve key sectors such as food processing, hydrocarbons, textiles, automotive, maintenance, and agro-industries, ensuring that each component meets the specific operational and hygiene standards required by each field.

Thanks to our advanced technology and skilled engineering team, we can design and manufacture stainless steel equipment and structures that adapt to diverse industrial and commercial needs. Beyond industrial applications, our expertise extends to stainless steel furniture for real estate projects, equipment for clinics, veterinary centers, laboratories, and funeral services, all manufactured with high-quality materials and exceptional surface finishes.

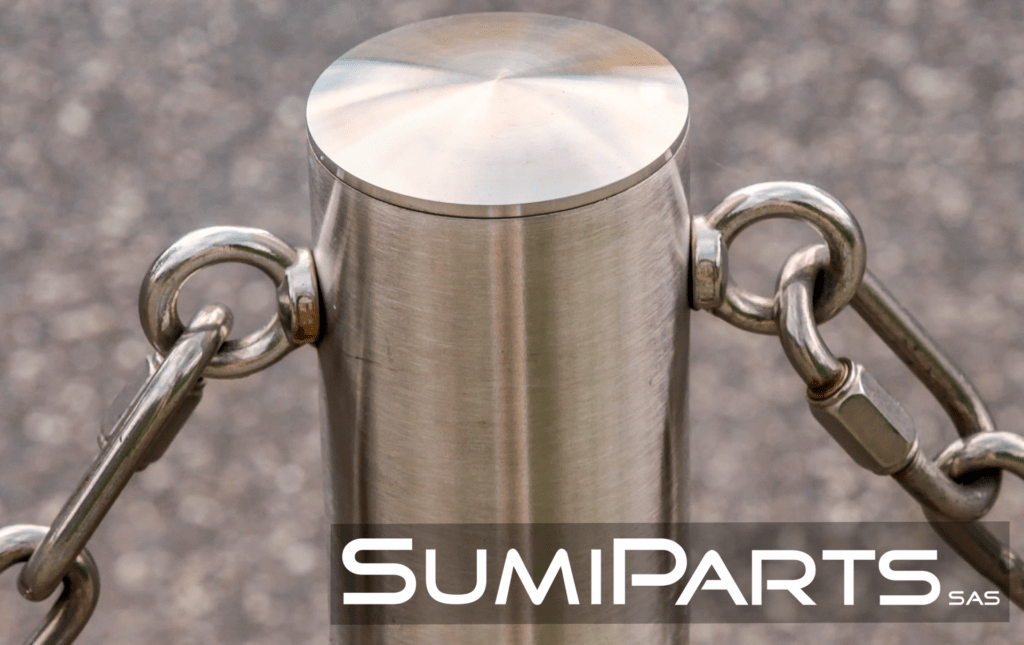

Our stainless steel fabrication services also support the construction and infrastructure sector, providing durable and corrosion-resistant components such as railings, handrails, frames, and support systems. We combine modern design tools with precision manufacturing processes to guarantee accuracy, strength, and an aesthetic appearance in each product.

At Sumiparts, flexibility is one of our greatest strengths. Whether you need a standard component or a fully customized stainless steel solution, our team is ready to develop products that meet your specific requirements. We work closely with each client to understand their technical needs, ensuring that the final result exceeds expectations in both function and finish.

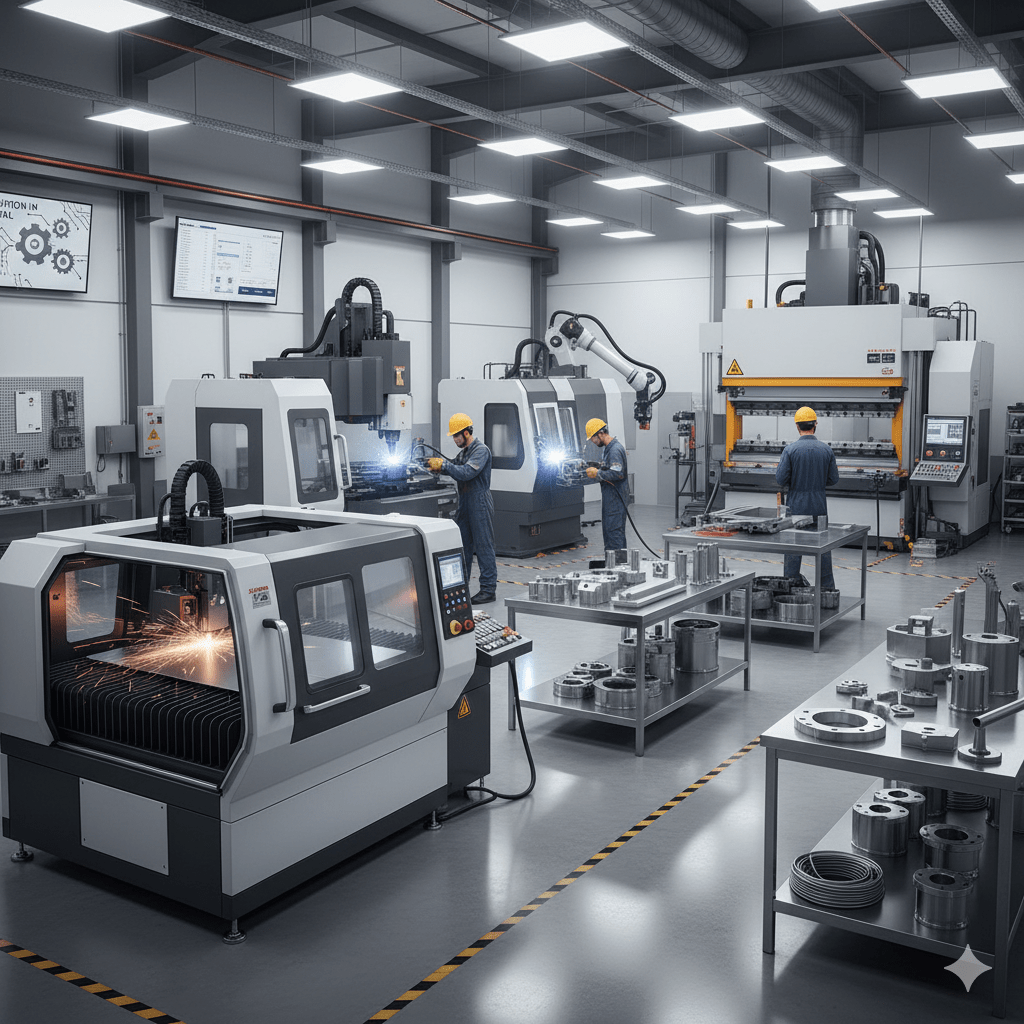

By integrating advanced CNC machining, laser cutting, and TIG/MIG welding technologies, Sumiparts’ stainless steel fabrication ensures high productivity, consistent quality, and versatility across all production scales — from individual prototypes to large-volume manufacturing.

Advanced Stainless Steel Fabrication Capabilities

Developing your stainless steel manufacturing projects with Sumiparts SAS offers multiple advantages in precision, technology, and efficiency. Our production plant is equipped with modern, high-performance equipment that allows us to execute complex operations and deliver superior results in every stage of stainless steel fabrication.

We provide a wide range of advanced manufacturing services, including:

Laser cutting for sheets and tubes, based on CAD models, ensuring high accuracy and smooth edges for even the most intricate designs.

CNC machining centers capable of developing complex parts with tight tolerances and consistent quality, ideal for industrial and mechanical applications.

CNC shearing machines designed for high-precision cutting of stainless steel sheets up to 3 mm thick, maintaining perfect dimensional accuracy.

Professional stainless steel welding, using TIG and MIG processes to ensure strong, clean, and durable joints suitable for structural and aesthetic applications.

CNC bending machines that provide flexibility for various bending requirements, allowing the creation of curves and shapes with consistent precision.

Each of these processes is integrated under strict quality control systems, ensuring that every product fabricated at Sumiparts SAS meets the highest industry standards. Our stainless steel fabrication capabilities allow us to handle everything from prototype development to large-scale production, always maintaining precision, reliability, and superior finishing.

Stainless Steel Manufacturing Possibilities at Sumiparts

At Sumiparts SAS, our stainless steel fabrication capabilities allow us to manufacture a wide range of products that combine functionality, durability, and modern design. Each project is developed with precision and attention to detail, ensuring that the final result meets both structural and aesthetic requirements across multiple industries.

Our manufacturing possibilities include:

-

Removable structures, safety boxes, and cans with innovative and ergonomic designs for industrial and commercial use.

-

Kitchen elements, shelving systems, and extraction hoods specially designed for the food and beverage sector, ensuring hygiene, resistance, and easy maintenance.

-

Dispensers, handrails, bins, and storage systems for the industrial and maintenance sectors, built to withstand intensive use and environmental exposure.

-

Pipes, tube bending, and customized handrails for the hydrocarbon and energy industries, offering high corrosion resistance and mechanical strength.

-

Structural parts and automotive components, including frames, supports, and fittings, tailored for performance and long-term durability.

Each stainless steel product fabricated by Sumiparts reflects our commitment to innovation and precision engineering. By combining advanced fabrication technology with expert craftsmanship, we provide flexible solutions that adapt to any industrial, commercial, or architectural application.

Precision and Technology in Stainless Steel Fabrication

All unified processes allow us to provide a better service to our customers and great freedom to develop any need that arises from the design of the part to the manufacturing process.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.