What is Styrene Butadiene Rubber (SBR)?

Styrene Butadiene Rubber (SBR) is one of the most widely used synthetic rubbers in the world, developed as a copolymer of styrene and butadiene. This elastomer offers excellent abrasion resistance, high flexibility, and great mechanical strength, making it a preferred material in multiple industrial and automotive applications. SBR maintains its properties under continuous stress, ensuring consistent performance and durability over time.

At SUMIPARTS SAS, we specialize in transforming SBR through advanced vulcanizing and extrusion processes. Our technical capacity allows us to produce custom components with excellent dimensional accuracy, resistance, and quality — ideal for large-scale production or specialized applications.

SBR Transformation Processes

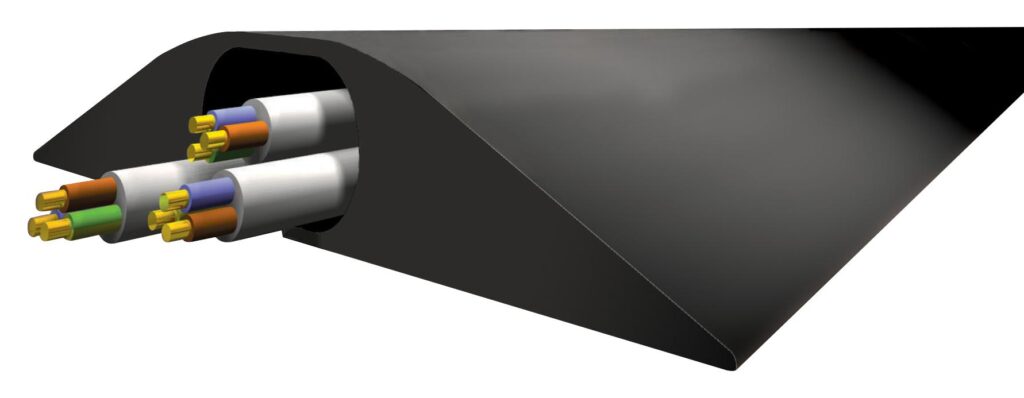

Through our vulcanizing process, we ensure SBR parts achieve maximum durability, elasticity, and structural stability. We also perform extrusion processes adapted to the specific geometry required by our customers, enabling the creation of continuous profiles, seals, and other technical parts with uniform quality and surface finish.

Industrial Applications of Styrene Butadiene Rubber (SBR)

Styrene Butadiene Rubber is used in a wide range of sectors thanks to its balance between flexibility, resistance, and cost efficiency. Some of its main applications include:

- Automotive Industry:

Styrene Butadiene Rubber plays a fundamental role in the automotive sector due to its excellent mechanical performance and durability. It is used in the manufacturing of tires, shock absorbers, seals, and vibration isolators, components that must endure friction, heat, and constant dynamic stress. SBR provides optimal traction, flexibility, and wear resistance, ensuring consistent performance and vehicle safety over long periods of operation. - Construction:

In civil and architectural works, SBR is widely applied in expansion joints, rubber flooring, waterproof membranes, and anti-slip supports. Its elasticity and weather resistance allow structures to absorb movement, temperature variation, and vibration without losing integrity. These features make it an essential material for bridges, industrial floors, and waterproofing systems that require long-term stability. - Industrial Manufacturing:

In the industrial field, Styrene Butadiene Rubber is highly valued for its versatility in conveyor belts, flexible hoses, gaskets, and mechanical buffers. These components must maintain reliability under continuous use, chemical exposure, and mechanical loads. SBR’s balance between toughness and flexibility extends equipment lifespan and minimizes downtime, making it a preferred choice in manufacturing plants, logistics systems, and heavy machinery. - Consumer and Everyday Products:

Beyond heavy industry, SBR is also found in footwear soles, protective components, rubber mats, and molded parts used in daily applications. Its ability to resist wear and deformation, along with easy processing through extrusion and molding, allows the creation of durable and cost-efficient products for mass consumption.

These uses make SBR a versatile and reliable elastomer for environments requiring both mechanical strength and flexibility.

Advantages of SBR Rubber

-

High resistance to abrasion and mechanical wear.

Styrene Butadiene Rubber offers excellent durability against friction and surface wear, making it ideal for continuous contact or movement applications. This characteristic ensures longer component life, especially in demanding environments such as automotive systems and industrial machinery.Good flexibility and recovery capacity under stress.

SBR maintains its elasticity and structural integrity even after prolonged deformation. Its capacity to recover its original shape allows it to absorb impacts, vibrations, and mechanical stresses without permanent damage, contributing to greater reliability in dynamic applications.Easy to process through vulcanizing and extrusion techniques.

This material adapts efficiently to industrial manufacturing methods such as vulcanization, molding, and extrusion. These processes allow the creation of complex geometries with precise tolerances, facilitating mass production and customization according to technical specifications.Cost-effective compared to other synthetic rubbers.

One of the main advantages of Styrene Butadiene Rubber is its balance between performance and cost. It delivers mechanical strength and durability similar to more expensive elastomers, offering a practical and economical alternative for large-scale production.Stable behavior in moderate temperature and dynamic conditions.

SBR maintains consistent physical and mechanical properties when exposed to moderate temperature variations, continuous movement, or vibration. This thermal and dynamic stability ensures reliable performance in diverse industrial environments without compromising quality or functionality.

Commitment to Quality and Production Capacity

At SUMIPARTS SAS, we have a highly specialized production team trained in the processing and transformation of Styrene Butadiene Rubber (SBR) and other high-performance synthetic elastomers. Our advanced manufacturing environment integrates precision tooling, controlled vulcanization, and extrusion processes that ensure every SBR component meets the strictest industrial standards.

Through a philosophy of continuous improvement, we focus on innovation and efficiency to optimize the mechanical performance, elasticity, and durability of each Styrene Butadiene Rubber part we produce. Our quality assurance systems guarantee uniformity across high-volume production, ensuring consistent results even under demanding technical specifications.

If you are looking to develop custom SBR components or want to explore industrial applications of Styrene Butadiene Rubber, SUMIPARTS SAS will be glad to support you at every stage — from design and mold construction to final production and quality validation. We take pride in delivering solutions that combine technical precision, flexibility, and long-term reliability.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click here, or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you.