Duralumin: Advanced Aluminum Alloy for Engineering

Duralumin is an advanced aluminum alloy composed mainly of copper, manganese, and silicon, belonging to the family of light alloys. This material stands out for its excellent mechanical behavior and low density, making it ideal for industrial and engineering applications where both strength and lightness are required.

Its main properties include high tensile strength, great mechanical resistance at room temperature, and good hardness levels, reaching up to 130 HB. Duralumin also provides excellent fatigue resistance and good corrosion performance, ensuring long service life and dimensional stability in demanding environments.

Benefits and Industrial Use Duralumin

This lightweight alloy is widely used in the industrial, automotive, aeronautical, and construction sectors thanks to its remarkable combination of strength, low weight, and excellent machinability. Its physical and mechanical performance make it one of the most efficient materials in engineering and manufacturing, especially in applications that demand reliability and energy efficiency.

Among its main benefits, the following stand out:

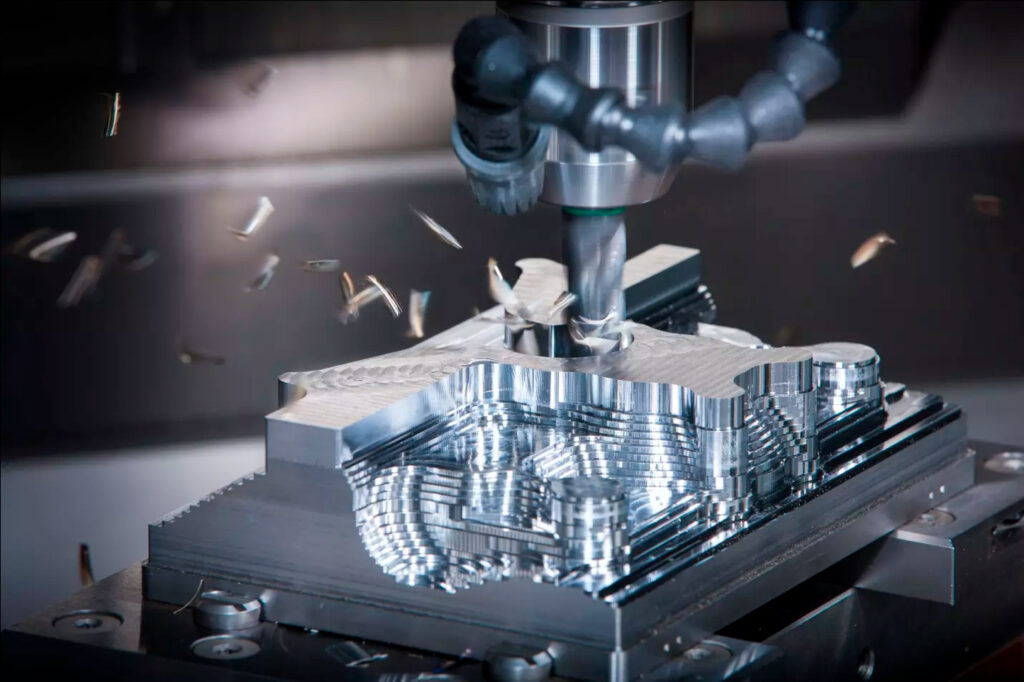

Excellent machinability: its composition allows faster and more precise cutting, drilling, and milling operations, reducing tool wear and improving productivity.

High resistance to corrosion: the protective oxide layer formed on its surface prevents degradation, even in humid or chemically active environments.

Outstanding wear resistance: ideal for components subject to friction or mechanical stress, ensuring longer service life and dimensional stability.

60 % lighter than steel: its low density makes it perfect for structures that require mechanical strength without excessive weight, such as frames, brackets, and aerospace components.

Good weldability: it allows solid, clean joints through specialized welding techniques, maintaining the integrity of the material’s structure.

Energy-efficient processing: due to its low cutting resistance and reduced machining effort, it minimizes power consumption and heat generation during production, resulting in lower operational costs.

Reduced machining time (70–80 %): thanks to its excellent chip formation and cutting performance, production cycles are significantly shortened without compromising precision or finish quality.

In SUMIPARTS SAS we are experts offering the following services in DURALUMIN.

CNC MACHINING IN DURALUMIN, taking into account the ease of machining, especially in chip removal and the great saving of time (70% -80%), represents the best option in a process where economy, speed and high efficiency are prioritized, with timely delivery and high production volume.

WELDING IN DURALUMIN, the best option when it comes to a unique material, where special welds such as the autogenous, represent the best option, thus guaranteeing the highest quality standards.

FOLDING AND BENDING IN DURALUMIN, we offer high production volume with precision, we put at your disposal state-of-the-art machines, with folding capacity at different angles and bending pressure developed by the numerical control method.

EXTRUSION AND INJECTION OF PLASTIC WITH DURALUMIN, for this procedure the mold in DURALUMIN material is essential, being the best option for obtaining high quality plastic products, and great durability of the molds.

THERMOFORMING WITH DURALUMIN, given the high demands that molds suffer during the thermoforming process, such as vulcanizing, SUMIPARTS offers the best service in developing DURALUMIN molds, the most economical option due to the great resistance to corrosion and high hardness of the material.

FINISHED IN DURALUMIN, the material can be reinforced superficially with different processes, where the gloss on the surface represents one of the most developed options. DURALUMIN itself presents high resistance against corrosion and excellent hardness.

SUMIPARTS SAS has an experienced team of staff, who with their knowledge and skills can provide an excellent service and final product tailored to the needs.

If you want to know more about developments in DURALUMINIO, in SUMIPARTS SAS we will be very willing to collaborate. We want to provide you with the best services at your fingertips.

Contact us by calling the Pbx: +57 748 22 13, mobile phones (+57) 313 699 13 56 WhatsApp click aquí , or by sending an email to info@sumiparts.us. Our technical team will be at your disposal to assist you. we leave you some links that may be of your interest Aluminum