What Is Platinum Rolling?

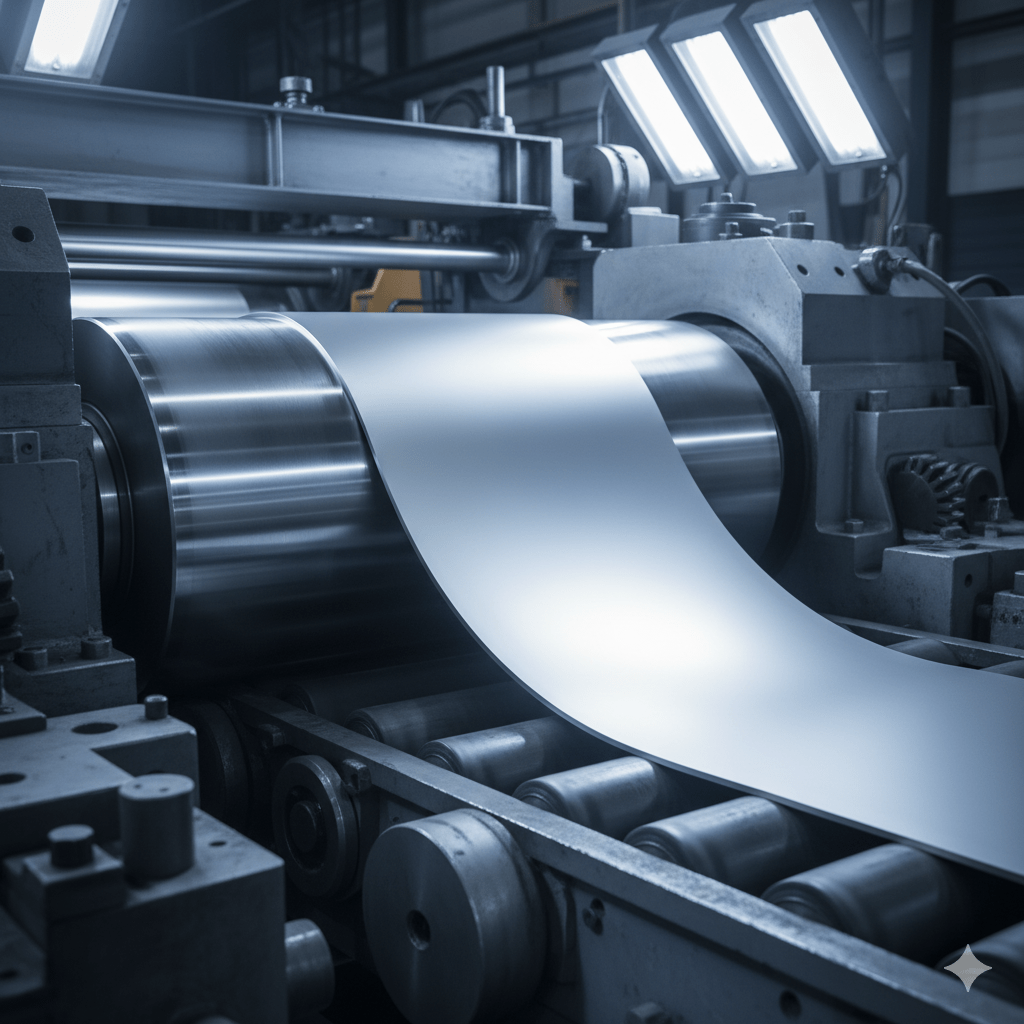

Platinum rolling is a metalworking process that involves passing flat bars or sheets through rollers to achieve the desired curvature, thickness, or shape. This technique is widely used in industrial manufacturing, construction, and metal fabrication, providing high precision and uniform results.

The process allows metals to be shaped without compromising structural integrity, making it suitable for applications where accuracy and consistent performance are critical.

How the Platinum Rolling Process Works

The platinum rolling process typically involves:

-

Material preparation: Cleaning and inspecting the metal before rolling.

-

Rolling through adjustable rollers: The metal passes between cylinders that apply controlled pressure to achieve the desired curvature or thickness.

-

Quality inspection: After rolling, the material is checked for uniformity, surface finish, and dimensional accuracy.

Modern rolling machines often include CNC controls for precise adjustments, enabling complex shapes and repeatable production runs.

Advantages of Platinum Rolling

Rolling metal with this method provides several benefits:

-

High precision: Ensures consistent thickness and curvature across the entire length.

-

Versatility: Suitable for various metals and thicknesses.

-

Efficiency: Reduces material waste compared to other forming methods.

-

Customizable shapes: Rollers can produce flat bars, curved sections, or special profiles according to specifications.

-

Improved surface finish: Maintains smooth surfaces with minimal post-processing.

These advantages make platinum rolling an essential process for industrial metal shaping and custom fabrication.

Applications in Industry

Platinum rolling is used across multiple sectors:

-

Construction: Curved steel supports, architectural elements, and structural components.

-

Automotive: Chassis reinforcements, brackets, and custom metal profiles.

-

Industrial machinery: Frames, protective guards, and equipment parts.

-

Custom metal fabrication: Decorative profiles, handrails, and metal artwork.

The process enables manufacturers to create high-quality, consistent components tailored to specific industrial needs.

Best Practices for Platinum Rolling

To achieve the best results with platinum rolling, consider:

-

Use properly prepared materials to avoid surface defects.

-

Adjust roller pressure and speed according to metal type and desired shape.

-

Inspect dimensions frequently to maintain precision.

-

Utilize CNC-controlled machines for complex or repeated shapes.

-

Maintain equipment regularly to prevent uneven rolling and ensure smooth surfaces.

Following these guidelines ensures a high-quality rolling process with minimal errors and consistent results.

Precision and Applications of Platinum Rolling

The rolling process for platinum is essential in achieving uniform thickness, reliable performance, and superior material integrity. By passing the metal through a series of carefully calibrated rollers, manufacturers obtain smooth, consistent sheets with minimal deviation in dimension or surface quality.

This high level of precision is vital for sectors such as aerospace, medical technology, and electronics, where even the smallest variations can compromise conductivity or durability. For example, rolled platinum is often used to produce electrical components, catalytic elements, and laboratory tools that must maintain their properties under extreme heat or chemical exposure.

Beyond its technical applications, this process also improves the workability of platinum. The resulting sheets, rods, and strips can be bent, welded, or machined to meet custom requirements. Each step in the rolling sequence enhances the internal structure of the metal, improving strength and surface finish while minimizing stress.

When integrated with advanced fabrication methods such as CNC machining or laser cutting, rolled platinum provides a stable and versatile base for precision components. This combination ensures efficiency, aesthetic quality, and dimensional accuracy across complex projects.

Conclusion

Platinum rolling is a versatile and efficient metalworking process that allows manufacturers to produce precise, uniform, and durable metal profiles. By combining advanced roller technology with proper material handling and quality control, companies can achieve consistent, high-quality results suitable for a wide range of industrial and custom applications.

If you would like more information about our sheet metal and metal rolling services, we at SUMIPARTS would be happy to assist you. We strive to provide you with the best possible service. You can contact us by calling our main office at +57 748 22 13, our mobile at +57 313 699 13 56, or by emailing us at info@sumiparts.com. Our technical team will be at your service.

To learn more about how rolled metal parts are prepared before assembly, explore our section on CNC turning and welding techniques.