Plastic Injection – Precision and Efficiency in Modern Manufacturing

Plastic injection is a widely used manufacturing method that allows for the production of high-precision and high-volume plastic components. By injecting molten plastic into molds under controlled pressure and temperature, manufacturers can create complex shapes with tight tolerances, making this process ideal for industrial, automotive, and consumer applications.

This technique supports rapid prototyping, custom part development, and large-scale production, offering both flexibility and consistency for manufacturers seeking reliable and cost-effective solutions.

Understanding the Plastic Injection Process

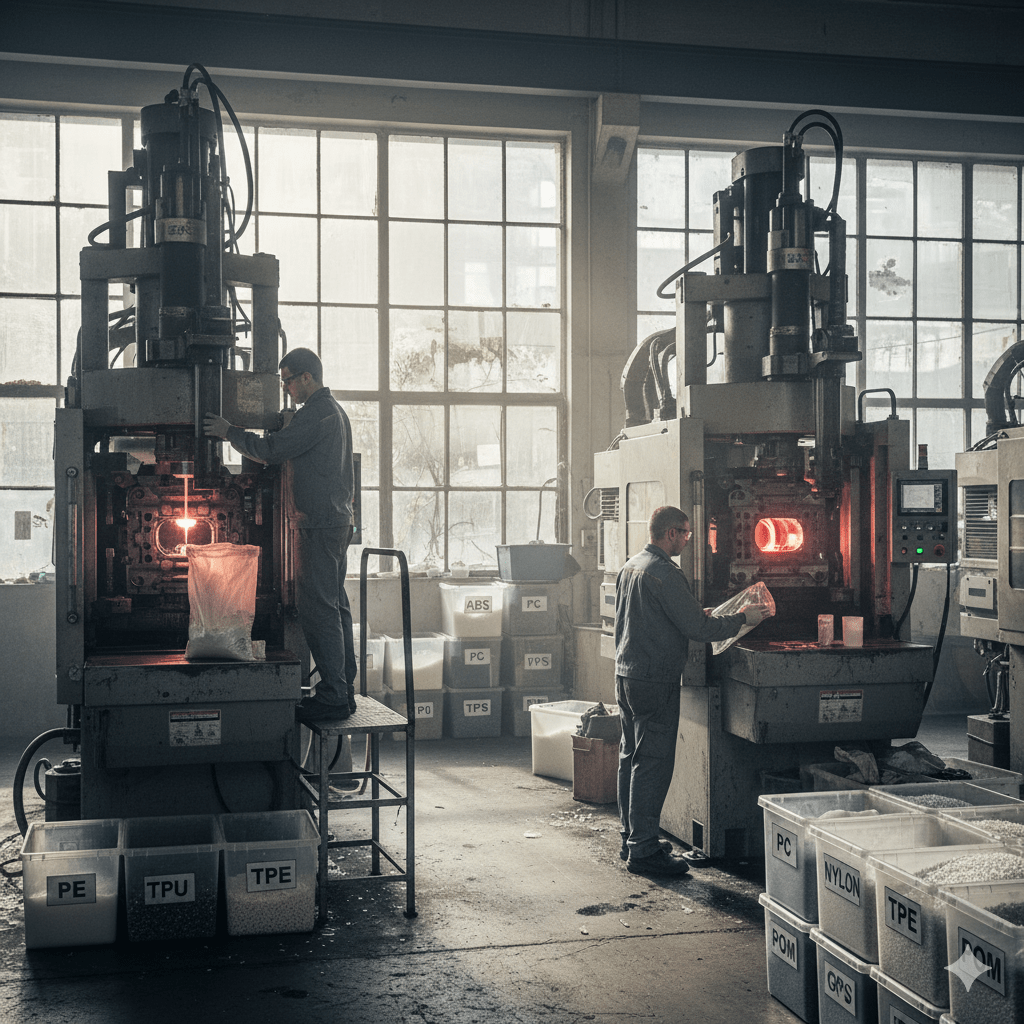

The plastic injection molding process begins with selecting the appropriate thermoplastic material, such as ABS, polypropylene, polyethylene, polycarbonate, or TPU. The raw plastic is melted and homogenized within a heated barrel before being injected into the mold using a hydraulic or electric injection system.

Once the plastic fills the mold cavity, it is cooled and solidified, taking the precise shape of the mold. After sufficient cooling, the mold opens and the finished part is ejected. Advanced injection machines use CNC-controlled systems to ensure reproducibility and high accuracy across every cycle.

Advantages of Plastic Injection

Plastic injection offers several clear benefits:

-

High precision: Produces components with exact dimensions and complex geometries.

-

Material efficiency: Minimal waste due to precise control over plastic usage.

-

Rapid production: Ideal for high-volume manufacturing.

-

Design versatility: Supports intricate features and multi-cavity molds.

-

Durable components: Plastic parts resist wear, corrosion, and chemicals.

These advantages make plastic injection a preferred method for industries requiring reliable, high-quality, and consistent parts.

Types of Materials Used in Plastic Injection

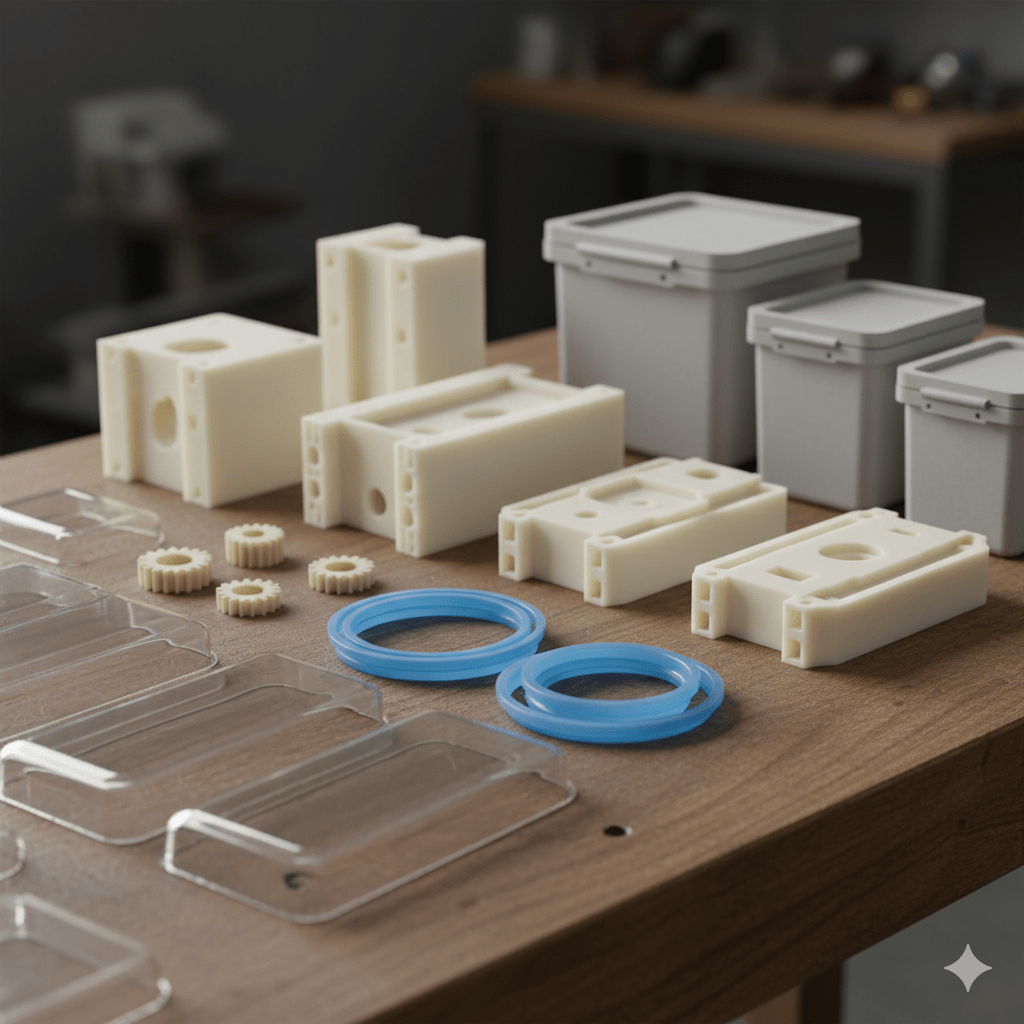

In the plastic injection process, selecting the right material is essential for achieving the desired properties in the final product. Each type of plastic offers unique characteristics, such as strength, flexibility, chemical resistance, impact resistance, or transparency, allowing engineers to tailor parts to specific industrial or consumer applications.

Some of the most commonly used materials in injection molding include:

Polyethylene (PE): A lightweight, flexible plastic with excellent chemical resistance, often used for containers, piping, and packaging.

ABS (Acrylonitrile Butadiene Styrene): A strong, durable material with good impact resistance, commonly used in automotive parts, electronic housings, and consumer products.

Polycarbonate (PC): A high-strength, transparent plastic ideal for protective covers, lenses, and electronic enclosures.

Polypropylene (PP): Known for its excellent chemical resistance, flexibility, and fatigue strength, often applied in automotive components, medical devices, and packaging.

Nylon (PA): Offers exceptional wear resistance, toughness, and low friction, making it suitable for gears, bushings, and mechanical components.

Thermoplastic Polyurethane (TPU): A flexible, abrasion-resistant material used for seals, gaskets, and protective coatings.

Thermoplastic Elastomer (TPE): Combines the elasticity of rubber with the processability of plastics, often applied in soft-touch grips, seals, and flexible parts.

High Impact Polystyrene (HIPS): A rigid, low-cost plastic with good impact strength, commonly used for housings, packaging, and prototypes.

Crystal Polystyrene (GPPS): Transparent and rigid, ideal for display products, light covers, and aesthetic components.

Polyacetal (POM): Also known as acetal, this material provides high stiffness, low friction, and excellent dimensional stability, making it perfect for precision mechanical parts such as gears, rollers, and fasteners.

Choosing the right injection molding material requires considering the part’s mechanical, thermal, and chemical requirements, as well as the intended environment and application. By selecting the optimal material, manufacturers can ensure that each part meets performance, durability, and aesthetic standards while minimizing production issues such as warping, shrinkage, or surface defects.

This diversity of materials is one of the key reasons why plastic injection molding is highly versatile and widely used across industries, from automotive and electronics to medical devices and consumer goods, allowing engineers to create functional, reliable, and visually appealing components in large volumes.

Plastic injection is intended for considerably high manufacturing batches, although the cost per piece is low, the cost of the mold is always a high investment, therefore, it must be analyzed in detail to proceed to the manufacturing negotiation.

At Sumiparts SAS we are experts on maximizing processes in an efficient manner, therefore, we offer the client the least possible investment, we guarantee the highest quality standards, our clients will also have the opportunity to develop various parts of complex geometries. At Sumiparts SAS , the Plastic Injection process is one of the most complete and positions us in the competitive market.

If you want to know more about the Plastic Injection, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.us. Our technical team will be ready to assist you.