Design and Development: Foundations for Efficient Product Manufacturing

Design and development is the basis within the manufacturing process of a product, that aims to capture all the parameters, procedures and tolerances for its development, thus providing a clear point of reference to develop the evaluation and quality control process on future occasions

The development of new products has become a key factor in achieving business success. If in the eighties all efforts were focused on reducing the manufacturing cycle and implementing flexible production systems, the nineties have been accompanied by a change in perspective and a concern for the process of design and development of new products. Especially due to the reduction of the time used in the design and development of new products.

Sumiparts SAS specializes in the Design and Developments of Products for multiple market lines that can be found in the metallurgical, automotive and construction fields.

The Design Phase – Conceptualizing Your Product

The first stage of design and development involves understanding the client’s requirements and translating them into a feasible concept. Engineers and designers collaborate to create 3D models, CAD drawings, and simulations that allow for virtual testing and visualization.

Key activities include:

-

Identifying functional requirements and constraints

-

Selecting materials and manufacturing methods

-

Generating preliminary sketches and CAD models

-

Performing virtual stress and performance simulations

This stage ensures that the product is technically viable, aesthetically appealing, and ready for prototyping.

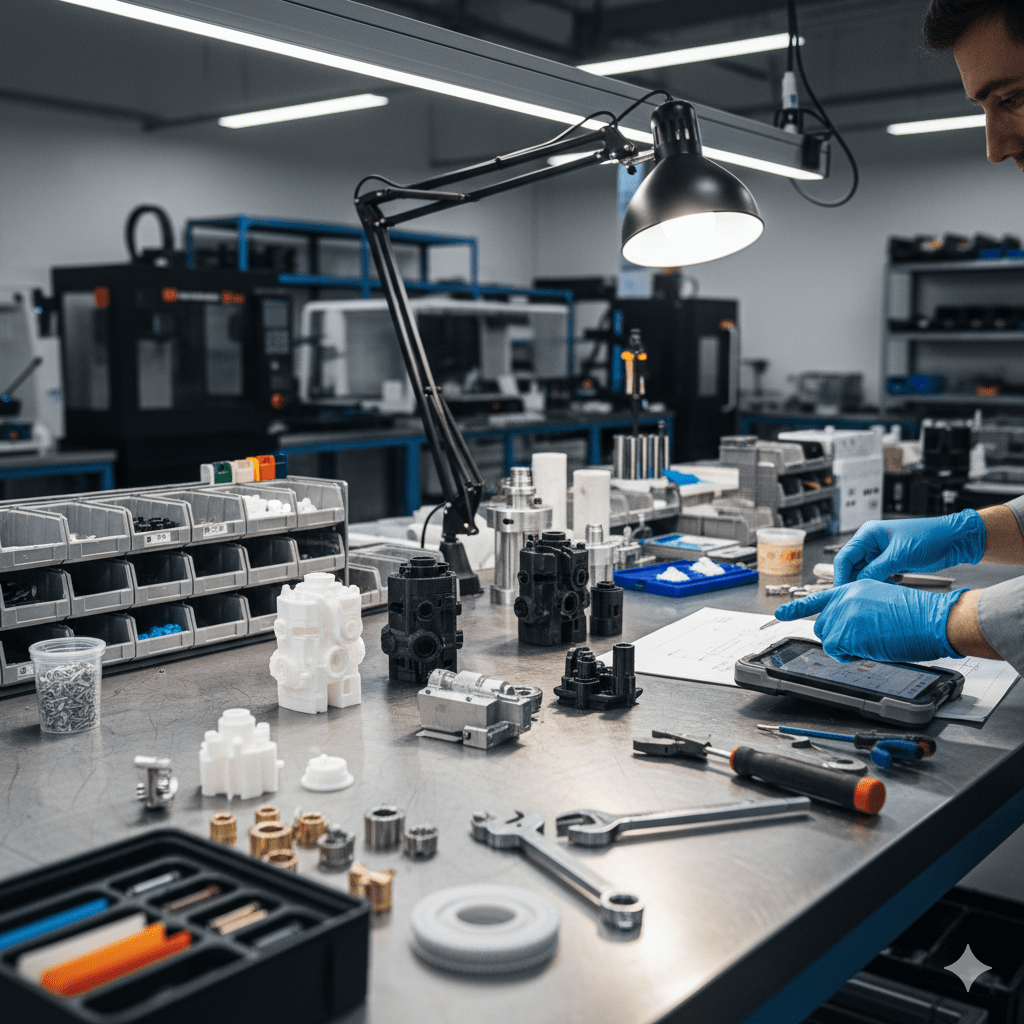

Prototype Development and Testing

Once the initial design is approved, the development phase focuses on creating prototypes. Using technologies like 3D printing, CNC machining, or small-scale injection molding, prototypes allow engineers to:

-

Evaluate ergonomics and usability

-

Test mechanical performance and durability

-

Identify design flaws and areas for improvement

-

Validate material selection and tolerances

Prototyping reduces risk by providing tangible feedback before full-scale production, ensuring the final product is optimized for both performance and manufacturability.

Engineering and Industrial Implementation

After prototyping, design and development moves to engineering and production planning. This phase involves:

-

Finalizing detailed CAD models for manufacturing

-

Designing molds, tooling, or fixtures

-

Preparing technical documentation for production teams

-

Integrating quality control measures to maintain consistency

Advanced simulation tools, CNC programming, and precise measurement technologies ensure that designs are replicable at industrial scale without compromising quality or functionality.

Benefits of Effective Design and Development

Investing in robust design and development processes offers multiple advantages:

-

Faster product development cycles

-

Reduced material waste and production costs

-

Enhanced product functionality and durability

-

Improved safety, usability, and aesthetics

-

Greater flexibility for customization and innovation

By combining engineering precision with creative design, companies can achieve products that are both high-performing and market-ready.

Applications Across Industries

Design and Development is used in a wide variety of sectors, including:

-

Automotive: Custom parts, dashboards, housings, and structural components

-

Electronics: Enclosures, connectors, and circuit board housings

-

Medical Devices: Ergonomic instruments, casings, and protective covers

-

Consumer Goods: Appliances, tools, packaging, and sports equipment

-

Industrial Machinery: Gears, brackets, protective shields, and assemblies

This versatility makes design and development an indispensable component of modern manufacturing.

Conclusion

Design and Development bridges the gap between concept and production, turning ideas into tangible, functional products. By leveraging CAD modeling, prototyping, engineering expertise, and industrial knowledge, companies can ensure that every component is optimized for performance, aesthetics, and manufacturability. Investing in this process guarantees quality, efficiency, and innovation across industries, from automotive and electronics to consumer goods and industrial machinery.

Focused on providing you with a specialized and professional design service for the creation of your ideas and followed by the manufacture of your products.

If you want to know more about the Design and Development service, at SUMIPARTS we are willing to collaborate with you. We want to provide you with the best services at your reach. Get in touch with us by calling Pbx: +57 748 22 13 Cel: 313 699 13 56 or by sending an email to info@sumiparts.com. Our technical team will be ready to assist you.